| Model | Capacity (m³) | Track width (mm) | Mass (kg) |

| 2000 ASR | 2 | 1500 | 930 |

| 2200 ASR | 2,2 | 1500 | 950 |

| 2400 ASR | 2,4 | 1500 | 960 |

| 2500 ASR | 2,5 | 1500 | 980 |

| 2600 ASR | 2,6 | 1500 | 990 |

| 2660 ASR | 2,66 | 1500 | 1000 |

| 2900 ASR | 2,9 | 1500 | 1010 |

| 2960 ASR | 2,96 | 1500 | 1050 |

| 3400 ASR | 3,4 | 1500 | 1115 |

| 3800 ASR | 3,8 | 1500 | 1165 |

| 4000 ASR | 4 | 1500 | 1180 |

| 4200 ASR | 4,2 | 1500 | 1250 |

| 4500 ASR | 4,5 | 1500 | 1250 |

| 5000 ASR | 5 | 1500 | 1320 |

The reliable partner

on the slope

The Stöckl side spreader stands for an optimal spreading pattern and comfortable, as well as efficient, operation.

We offer attachment components to fit our spreaders to all common transporters, as well as special solutions for vehicles outside of our standard program upon request

-

Models

-

Mistral

-

Economy

Model Capacity (m³) Track width (mm) Mass (kg) 2000 ASE 2 1500 930 2200 ASE 2,2 1500 950 2400 ASE 2,4 1500 960 2500 ASE 2,5 1500 980 2600 ASE 2,6 1500 990 2660 ASE 2,66 1500 1000 2900 ASE 2,9 1500 1010 2960 ASE 2,96 1500 1050 3400 ASE 3,4 1500 1115 3800 ASE 3,8 1500 1165 4000 ASE 4 1500 1180 4200 ASE 4,2 1500 1250 4500 ASE 4,5 1500 1250 5000 ASE 5 1500 1320

-

-

Tyres

Standard tyres

Model Tyre 2400 AS 11,5/80 - 15,3 AW 2200 AS 11,5/80 - 15,3 AW 2400 AS 11,5/80 - 15,3 AW 2500 AS 11,5/80 - 15,3 AW 2600 AS 11,5/80 - 15,3 AW 2600 ASO 10,0/75 - 15 AW 2900 AS 15,0/55 - 17 AW 2900 ASO 10,0/75 - 15 AW 3400 AS 15,0/55 - 17 AW 3800 AS 15,0/55 - 17 AW 4000 AS 15,0/55 - 17 AW 4200 AS 15,0/55 - 17 AW 4500 AS 15,0/55 - 17 AW 5000 AS 15,0/55 - 17 AW Alternative tyres

Alternative tyres only available at an extra charge. For further information, please contact us or our sales partners.

Order Nr. Description SSZ020 from 11,5/80x15,3 AW Farmer to 11,5/80x15,3 AS Farmer SSZ018 from 11,5/80x15,3 AW Farmer to 15,0/55x17 AW Farmer SSZ110 from 11,5/80x15,3 AW Farmer to 15,0/55x17 AS Farmer SSZ022 from 15,0/55x17 AW Farmer to 15,0/55x17 AS Farmer SSZ019 from 15,0/55x17 AW Farmer to 19,0/45x17 AW Farmer SSZ038 from 15,0/55x17 AW Farmer to 19,0/45x17 AS Farmer SSZ032 from 15,0/55x17 AW Farmer to 425/55x17 MPT AC70 SSZ021 from 15,0/55x17 AW Farmer to 550/60x22,5; track width of 1700 mm required SSZ116 from 15,0/55x17 AW Farmer to 500/50x17 -

Tech

Click on the different headlines, for an throughout description.

-

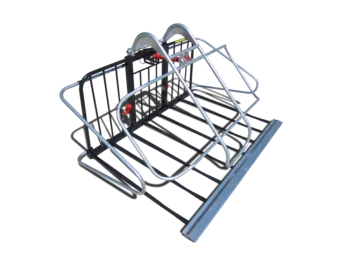

Hydraulic scraper floor drive

The powerful hydraulic scraper floor motor drives the scraper floor chain. The scraper floor rails are attached to the scraper floor chain with clamping elements, allowing them to be rearranged, exchanged, added, or removed at any time as desired.

The chain also benefits from this type of attachment, as it can be designed as a continuous chain, making it more stable.

-

-

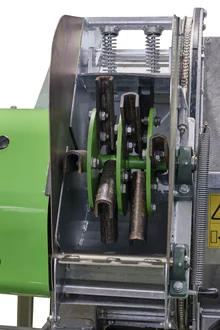

Turbine

The spreading material is first chopped up in the turbine by the planetary cutter and then transported to the spreading unit by the feeder rotor. The planetary cutter and the feeder rotor are mechanically driven by a chain drive from the PTO shaft. Depending on the size of the side spreader, three or four blades are installed on the planetary cutter to ensure that the spreading material is optimally chopped. These blades are robustly designed and can be sharpened if necessary.

For cleaning after spreading, the turbine is equipped with a cleaning flap. This can be opened to comfortably remove any residues in the turbine during cleaning.

-

-

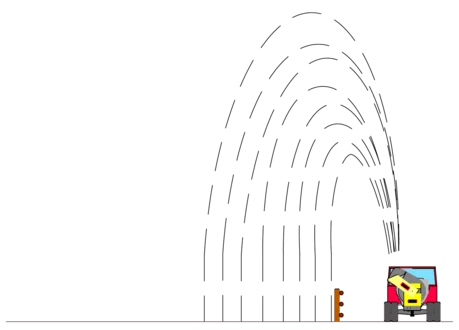

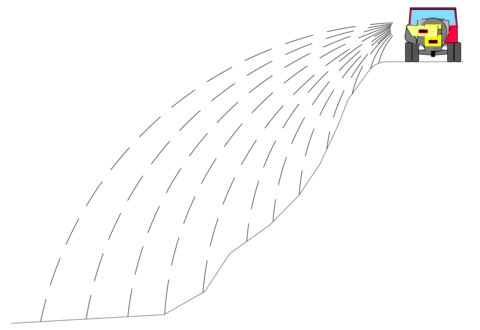

Spreading unit

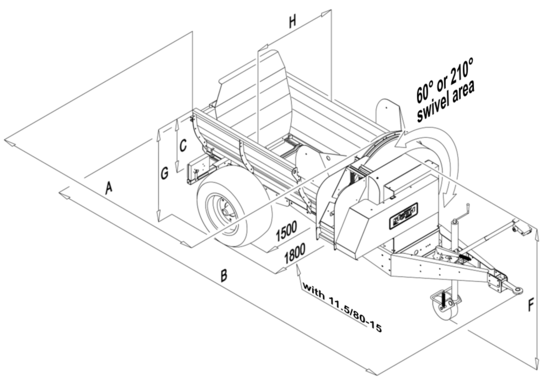

Because the spreading angle is adjustable it is possible to position the spreading material precisely, which results in more efficiency when fertilizing and frustration free working conditions.

We offer two types of spreading units.

The Mistral series , which can rotate the spreading unit 210° and the slightly less expensive Economy series, which can rotate 60°.The hardened beater knives ensure an optimal and fine distribution of the spreading material. By hardening the wear resistance of the beater knives is vastly improved, ensuring an long lifetime.

The fine spreading pattern helps reducing weed growth and enables fertilizing inbetween growing seasons since the spreading material rots faster due to the smaller particle size.

-

-

Requirements for the drive vehicle

For operating our Lateral Manure Spreader the driving vehicle must be equipped with two double-acting control units. For vehicles without onboard hydraulic system or with only one control unit we offer the following optional addons:

If you have any questions or require further assistance, please do not hesitate to contact us or our sales partners.

Option Description Changeover valve For vehicles with only one double acting control unit. Supplementary control unit Attached to the spreader, ideal for vehicles with an single acting control unit(for example: Tilt connection + return or only one double-acting control unit) Hydraulic accumulator For actuating the swiveling motion on the spray unit with an single acting control unit Spray volume regulator Suitable for vehicles equipped with an hydraulic system without flow regulator, for continuously variably adjusting the speed of the scraper floor. Hydraulic accumulator with spray volume regulator and control unit For vehicles without onboard hydraulic system

-

-

Specialized Solutions

For special applications such as in orchards or plantations, we offer special versions of our spreaders adapted on those conditions.

The machines can also be fitted with special tyres and a steering axle to increase manoeuvrability.

Our engineering department will find the right solution for you!

-

Media

Videos

-

-

How-To's

Maintenance

Helpful maintenance tips and tricks in video form

-